Bronze Haast Cast Eagle

Investment Casting

Bronze casting by the talented sculptor Al Brown from Hokitika. Bronze Haast Eagle head on Matai stand. Cast in Read Industrials lost Wax foundry.

Bronze casting by the talented sculptor Al Brown from Hokitika. Bronze Haast Eagle head on Matai stand. Cast in Read Industrials lost Wax foundry.

Lost wax casting in bronze for iconic Artist Ashley Smith.

The Waves on the platform do get a lot of wear and tear from the cows. If your old waves are broken, cracked or coming loose the option is there to upgrade to the longer, bolt down type wave. These can be installed onto either concrete or steel deck platforms. Get your quote today >>>CLICK HERE

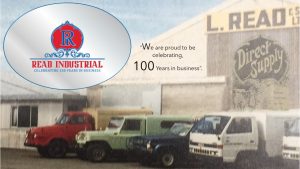

While it’s been 100 years since the business was launched from a Papanui garage – and more than five decades since its move to Rangiora (1965-1966) – Reads remains a rare commodity in a fast-paced world.

A time-honoured business that has never wavered from its course to serve and to support its clients.

We complete the entire project from start to finish. Design, in-house machining & finishing.

Internal 40 bail sheep milking system. Pulsations rates, clusters, vacuum levels, and pipeline sizes have been adjusted to suit the lower milk flows that we get. The owner put his trust in Reads to design and build a system that fulfilled his requirements.

Internal Sheep Milker

Simple technology that adjusts based on cow flow. Teat spraying that’s suitable for Pre and Post milking. Compatibility with rotary and herringbone sheds.

“It’s great to be finished this New Shed the 54-bail Read Milking Machine in Fairlie. Setting the pace, it was completed in 2-months from the last cow walking out of the old shed. The build started with driving a bulldozer through the old shed 45 Bail herringbone shed and building the new shed on top of the old footprint. Builders and engineers battled getting concrete and steel onsite due to severe weather causing damage to roads and bridges being down. Thus, the excavation site had to be constantly pumped out during the entire build. Said, Andy Garth “Senior Read Milking Technician”.

Read Milking Systems is at site G90, 16-19 June at Mystery Creek Events Centre in Hamilton. Join us at the biggest agricultural show in the southern hemisphere.